How Next-Gen Automotive Engineers Are Educated

The EcoCAR competition is nearing its three-year end. Along the way students have gained an amazing education in hybrid vehicle design. But that's just the beginning.

- By Dian Schaffhauser

- 01/04/11

The new generation of cars won't necessarily be thought up by the engineers who have spent their careers improving the combustible engine. That's technology whose time is fading. Foreseeing that eventuality, United States and Canadian government agencies and industry megaplayer General Motors have developed a program--EcoCAR: The NeXt Challenge--to push students and their universities to re-engineer both vehicles and curriculum to address new modes of automotive design. Along the way EcoCAR has also helped students get a jumpstart into their chosen professions, changed the way car companies hire graduates, and offered up fresh ideas to professionals in the businesses that cater to the automotive segment.

Mississippi State University is one of 16 higher education contenders in EcoCAR, a three-year competition that's currently wrapping up its third year. In May 2010 the university took first place in the Year 2 Finals. The competition challenges engineering students to re-engineer a GM-donated vehicle to minimize the vehicle's fuel consumption and emissions, while maintaining its utility, safety, and performance.

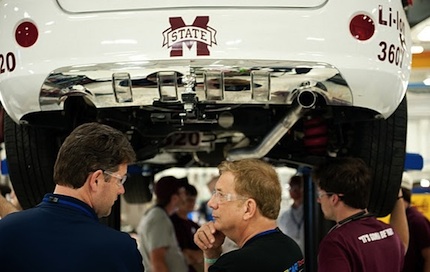

MSU students train on the tools they use for the EcoCar Challenge. |

EcoCAR comes out of a 20-year effort by the Department of Energy to give people the chance to design and build advanced vehicles that demonstrate leading-edge automotive technologies. In those two decades the DoE has run 45 competitions. For the latest one, which is strictly for students, General Motors provides production vehicles, vehicle components, seed money, technical mentoring, and operational support. The DoE and its research and development facility, Argonne National Laboratory, provide competition management, team evaluation, and technical and logistical support. Then a cadre of other interested entities--such as MathWorks, which sells high-end mathematical computing software for engineers and scientists--also provide support by donating industry-caliber products and training to participants.

Students have followed a design process that mirrors GM's own Global Vehicle Development Process, spread across the three years of the competition. In the first year competitors received a heavy dose of modeling and simulation. The work they did--frequently outside of regular classes--emphasized the use of math-based design tools and the development of simulation techniques. After researching, comparing, and selecting advanced technologies that met the competition and team goals, students used $10,000 in seed money to procure hardware for developing and testing their powertrain and other vehicle subsystems.

During the second year, all teams that completed the first year goals received a Saturn VUE, a crossover vehicle from GM (no longer in production), to rebuild from the tires up. That work culminated in a gathering of teams for a week-long set of engineering tests, similar to the ones GM conducts to determine how ready a prototype is for production. In fact, this piece of the competition actually took place at in Yuma, AZ at GM's Desert Proving Grounds. Each car was evaluated based on its ability to decrease fuel consumption and greenhouse gas emissions and retain consumer acceptability in the areas of performance, utility, and safety.

Mississippi State took first place in this competition. The student team designed a plug-in extended range hybrid with a 21.3 kilowatt hour battery pack from A123 Systems that provides an electric range of 60 miles. The car was also equipped with a 1.3 L GM turbodiesel engine and 75 kW UQM generator. During testing, the vehicle's fuel economy achieved the equivalent of 118 miles per gallon combined city/highway driving. The university also won nine additional awards, including performance events in auto-cross and acceleration and best outreach promotion.

Year 3, the current year, focuses on implementation and refinement of the vehicle technologies. In June 2011, the teams will gather once again to participate in events that allow them to show the progress they've made and to declare an overall winner for the year. "We did really well last year," said Brian Benoy, Controls Group team lead for Mississippi State. "Now we want to do even better by going back and looking at things we didn't have enough time to do last year and coming back this year with an even stronger vehicle that gets even better mileage. We're hoping to beat our 60 miles all-electric range."

"And if it doesn't beat the range, they'd like to beat the speed," added Marshall Molen, a professor of electrical and computing engineering at Mississippi State and faculty advisor for the university's EcoCAR team. "They'd like to take a family car and convert it into a racecar."

Molen insisted that all the engineering is done by the students. "I'm there to help them with roadblocks that may come up, especially dealing with our university and [identifying] resources." He tries to organize the efforts for the competition "almost like a company." The team has a main leader and department heads, all graduate students. He said he looks to them to mentor young people within each department and also to serve as role models. The structure has been extremely effective, he said.

"Department heads" oversee efforts in six areas: electrical, controls, powertrain/mechanical, emissions, and outreach. Within each are "subset" team leaders, who tackle specific projects, and team members. The current roster for Mississippi State lists 34 people in total, most in mechanical, electrical, or chemical engineering.

But non-engineering students are also invited to participate as part of the outreach team. According to Lee Pratt, a business graduate student and the current outreach leader, her group takes care of public relations work, documenting its media coverage (which has been considerable since its latest victory), and updating the EcoCAR Web site for the school.

After its 2010 win, the students were feted on the field of the university's first home game and the university president held several meetings with them. A November homecoming parade included the EcoCAR team, which drove its vehicle along the path "of cheering fans," as a blog entry reported.

MSU's EcoCar vehicle |

All of the attention in turn has helped in recruiting efforts. A September interest meeting attracted a hundred potential team members. That's good news because, as graduate student Benoy explained, the biggest challenge lately hasn't played out in the battery technology or in powertrain problems; it's been organizational. "From year to year, you have turnover because you have students graduating. We're always looking for new students to join the team to replace the veteran students who graduate and go off into the industry." When new people join the team, they have to be trained, he added. "We're always having to catch the new kids up with the history of the vehicle if they're starting in the middle of the competition. There's a fairly steep learning curve, especially in the later years of the competition."

EcoCAR has also helped draw new students to the university--or least their parents. Benoy has given tours to prospective students. "Their parents have specifically sought out Mississippi State and our EcoCAR team to get a tour from us, to see what we're doing and actually see the car they've read about. We're starting to get a following."

Of course, it's not all meet-and-greet and playing to the press. Those who get involved practically live the EcoCAR experience. Benoy called it "a full time job with class on the side." Students have been known to sleep in the "Green Garage," the name given to the space where students work on the vehicle.

Outreach coordinator Pratt concurred on the intensity level the work calls for. During the first year she participated in events and then was wooed into taking on the top job for outreach. "You go to bed working on this," she said. "You wake up and work on it. It's not just the number of hours that I'm sitting down in front of my desk. The work you put into it is constant."

That commitment also involves training sessions where sponsors bring all student teams together for classes in specialized topics. The latest training session, held in fall 2010 outside of Boston at MathWorks' headquarters, allowed students to learn about new rules and regulations, deliverables, and vehicle testing for Year 3 of the competition. They also took workshops in their specialties, including optimizing controllers for energy management, creating 3D virtual environment simulations, emissions testing, vehicle safety, and MathWorks software training.

"You couldn't over-emphasize how important the training is," Molen declared. "These students are having the opportunity to work with the most modern software tools available in the industry. Not only do they have access to extremely expensive tools, but they're being trained by the experts." MathWorks brought in consultants from their offices in Michigan to assist with some of the specialized training. "It would be very difficult to even put a price tag on what our students are receiving at this kind of training," he added

Paul Smith, MathWorks director of consulting services and technical lead for the company's support of the EcoCAR competition, said he views the payback as a two-way street. "We see new use cases, new requirements, new perspectives on how things should get done. Students are perhaps more creative than seasoned grizzled vets of the automotive industry. They challenge more. They question more. They don't accept the constraints that many of us are kind of beaten down to accept," he observed. "It's very refreshing. That's why I'm involved. That's why my team of technical consultants is involved. It gives them some joy as 'enginerds' to see this kind of excitement around things that we also are excited about."

Industry involvement has been vital to the development of curriculum at Mississippi State, Molen said. "Otherwise, it wouldn't be relevant. You wouldn't have access to the expertise. If we were just using what was available to us otherwise, we could not be teaching what is current. We could not be using the sophisticated hardware and software tools that we have." Likewise, students are making life-long industry connections. "Our kids call these folks up on the phone and say, 'Paul, I have a crisis....' I think that's really important."

His university has developed a certificate program in automotive engineering to acknowledge the work done by students beyond their required engineering courses. "The diploma is worth a little more," he noted. "But the certificate does tell [prospective] employers that you've had a focus to some of your studies."

The fact that the students are learning how to apply the processes developed by GM for its own vehicle work introduces them to a "capacity for complexity," said MathWorks' Smith. "When you start thinking about these plug-in extended range hybrid vehicles, the technology is mind-boggling. There's more computer software and controls in these hybrids than in fighter planes, and to pilot a fighter plane takes two years of training. Yet any casual user can get in and turn the key and drive a hybrid away without any special training."

The bottom line is that the next generation of engineers is coming out of college ready to participate immediately in the design process for the most advanced vehicles in the automotive industry. "General Motors is snapping up people out of this program right and left and putting them right on programs like the Chevy Volt and other future programs that require this kind of stuff," he said.

Graduate student Benoy acknowledged that the competitions draw executives from GM and other sponsors. "We all know that they're watching us. So it feels good to have your team do well. That helps with your networking abilities." He added that GM executives have told him that the vast majority of hiring in the foreseeable future will "be strictly through EcoCAR. That's good news for someone like me who's involved."

Participating students have also secured internships and jobs at other sponsors, including A123 Systems, National Instruments, dSPACE, and others. The job prospects don't apply simply to the engineering students either. Molen said the team's first outreach coordinator is now working as a contractor for the DoE on the EcoCAR project--"and she's having an amazing career."

Come June, when the teams gather for their final drive-off, the Mississippi State team will once again have to prove its prowess against its 15 competitors. In the meantime, the university also has to decide whether it's going to enter the DoE's recently announced EcoCAR 2, another three-year competition for colleges and universities in North America. Responses to the organization's request for proposals are due in mid-January. From those proposals Argonne and its selected experts will choose 16 competitors again. Institutional winners will be announced in March 2011, and the cycle will begin all over.

About the Author

Dian Schaffhauser is a former senior contributing editor for 1105 Media's education publications THE Journal, Campus Technology and Spaces4Learning.