Print Your Own 3D Learning Objects

As 3D printing grows in sophistication, the technology is moving from cool trick to learning tool.

- By Dian Schaffhauser

- 12/04/13

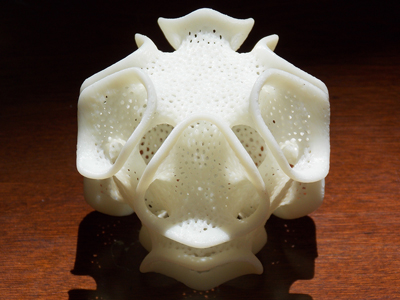

A 3D-printed mathematical object. Photo courtesy of Nick Crowl, DeLaMare Science and Engineering Library, University of Nevada, Reno |

The 2013 Horizon Report estimates that 3D printing is still four to five years away from widespread acceptance in higher education, yet early adopters are growing in numbers and sophistication. The rapid rise in the technology's popularity seems to owe much to educators discovering its inherent value as a learning tool.

Jon Mehlferber, on the Department of Visual Arts faculty at the University of North Georgia, for example, loves what 3D printing can teach students about production processes--from concept and design to modeling, producing, and, ultimately, holding the finished product in their hands. "I think it's a great way to connect all those dots that otherwise would be just abstract ideas," he says.

Mehlferber partnered with Terrie Millard, a faculty member in the Department of Physical Therapy, on a grant proposal to have PT students use 3D printing to create low-cost orthotics and assistive devices for disabled children. With traditional orthotics, it can take weeks to get a specialty part created. Because children are growing constantly, the recipient may have outgrown the device by the time it arrives. With 3D printing, on the other hand, the part can be designed, modeled, and printed on one day and fitted the next. "That's incredible for the field of adaptive devices," Mehlferber says.

Mehlferber and Millard called on students in visual arts, biology, and physics to handle the design and construction of the devices, while PT students offered advice and guidance on the types of objects to be produced. One undergraduate participant was so influenced by the experience, she chose to learn how to become an orthotist, a person who makes orthotics. "It's exciting to have [had] that influence," Mehlferber says.

Justifying the Expense

Until 3D printers can mint their own money, though, educators will need a compelling educational rationale like Mehlferber's to justify the expense. The printers themselves cost anywhere from $2,000 to $30,000, not including the rolls of plastic filament or modeling software. As Mehlferber himself discovered, few schools in today's lean budget environment are willing to bankroll an untried technology on a whim. His original grant application to the university's Center for Undergraduate Research and Creative Activities proposed making the technology available to students in any major "to see what they could come up with," he says. That grant was turned down.

But, as Mehlferber's successful proposal shows, 3D printing can be of enormous value as part of a pedagogical model that stresses cross-disciplinary study and/or collaborative teams. By pushing students to develop additional skills, 3D printing projects can open student eyes to opportunities that they might never have considered. At the University of Nevada, Reno, for example, Tod Colegrove, director of the DeLaMare Science and Engineering Library, has been sending students to Lynda.com for training on how to use 3D modeling programs to generate the STL files used by the university's specialized printers. He recalls how one political science major wanted to build zombie fingernails for a campus game of Humans vs. Zombies. After several hours of training, the student returned, model in hand and ready for printing. "He's now one of our lead 3D printing and wrangling folks," says Colegrove. "Who knows what he's going to become, but I can promise you that he knows now he can do things he had never dreamed of. That's going to take him so incredibly far."

Initially, Pamela Zelbst feared that introducing 3D printing in her classes at Sam Houston State University (TX) would turn out to be more technical than her management majors could handle. But using a 3D printer, says the director of the Sower Business Technology Lab, "is like sending a Word document to an inkjet printer. There is nothing overly complicated about it."

Now her students are expected to integrate 3D printing into projects for their operations courses. "It opens their eyes to technologies and what the implications are for business," says Zelbst. "From a business perspective, we hear about digital manufacturing. That's 3D printing. We hear about product design [and] time to market. The way you're cutting down on that is through 3D printing. You have a product that you have printed, packaged, and sold. You could do it that way, or if people have home printers, they could just download a file that you're selling online and print that object."

If a design doesn't already exist (on a design portal such as MakerBot's Thingiverse) for what a student needs, he must find resources to help do the design work--just as a business would. "The whole idea is to give students that real-world experience," says Zelbst. "Plus, at the end of the project, they've gotten to do something really cool that they can put on their résumés and take out to the workforce, and they've got something to talk about when they're being interviewed."

Getting Attention

To generate the buzz Colegrove wanted for UNR's 3D printer, he gave it space right in the library atrium where everybody using the facility passes by. "We've become a very central stop on the campus tours because of that," he explains. "The new students and parents all walk through the atrium, and we get a chance to talk with them."

The printer can be used by any staff person with training on how to read the machine's interface and change the rolls of ABS plastic that produce the 3D object. Colegrove and his staff have put processes in place to streamline the work: For example, the name of every print job, which appears right on the printer screen, starts with the color of plastic that should be used in the printing process.

For several months, UNR ran its 3D printing as a free service. Anybody--student, staff, or faculty member--could use the printer for whatever they wanted as long as it fit within the size parameters of about 8 inches by 8 inches by 6 inches. Hundreds of print jobs were done during that period, and library staffers tracked how many cubic inches of plastic were used to print each type of model. According to their calculations, every cubic inch of ABS cost about $7.20. Armed with that data, the library implemented a cost-recovery model to cover the expense of buying the plastic filament used by the printer.

|

You Get What You Pay For

Don't plump for a low-cost "hobbyist" 3D printer unless the business case you're making is that students will learn lots by tinkering with it. When it comes to 3D printers, you get what you pay for.

When the Department of Chemistry at the University of Nevada, Reno came to Tod Colegrove, director of the school's DeLaMare Science and Engineering Library, with the idea of purchasing a 3D printer for use in the library, it specified the ability to print in "real material--something they could machine or drop without breaking," notes Colegrove. Many of the low-cost printers under consideration would have been unable to meet that goal. "Our local Makerspace had a MakerBot," he adds. "They scared us hard away from it. They thought it was cool, but they were always having to dink with it to try to keep it going."

Eventually, UNR settled on a uPrint SE Plus from Stratasys, whose models retail for $19,000 to $28,000. Next, the university acquired a 3D Touch (now discontinued; previously built by 3D Systems) that cost between $4,000 and $5,000. The uPrint is a workhorse that churns out an average of four to five printed objects a day--a total of 1,642 pieces since its deployment. Acquired in August 2012, the printer just went through its 6,000-hour tuneup. The Touch, on the other hand, has probably had no more than a hundred hours of usage. "It hasn't been stable," says Colegrove. "In an environment like the library, I can't afford to have people on staff paid just to dink with the cheaper equipment."

|

In addition, a staff person now reviews each plan and will sometimes recommend improvements--such as making the model hollow instead of solid to save on printing time and filament expense. The student then pays the fee, a receipt is generated, and the plan goes into the print queue. Typically, says Colegrove, there's a two-day turnaround on jobs.

As a result of this vetting process, the quantity of objects being printed has "toned down," but the library still sends the same overall number of jobs to the printer. "That says to me that folks are being a little more cautious," Colegrove suggests. "They're not printing 10 copies of this widget. They just need three."

About the Author

Dian Schaffhauser is a former senior contributing editor for 1105 Media's education publications THE Journal, Campus Technology and Spaces4Learning.