Reverse Career Fair Puts Student Projects on Display

- By Dian Schaffhauser

- 02/25/19

A Wisconsin university held what it called a "reverse career fair." Instead of students wandering around a hall introducing themselves to potential employers that were showing off their companies, the employers did the moving and introduced themselves to engineering students who were displaying their maker projects.

Georgia-Pacific's Arrine Lyman (left) discusses a planetary rover with the students who built it. Photo by David Tenenbaum.

The University of Wisconsin-Madison career event showed off a prototype for a Mars rover and a "nerdward watch," according to a campus article.

Also on display, the university's makerspace, which is housed within the College of Engineering.

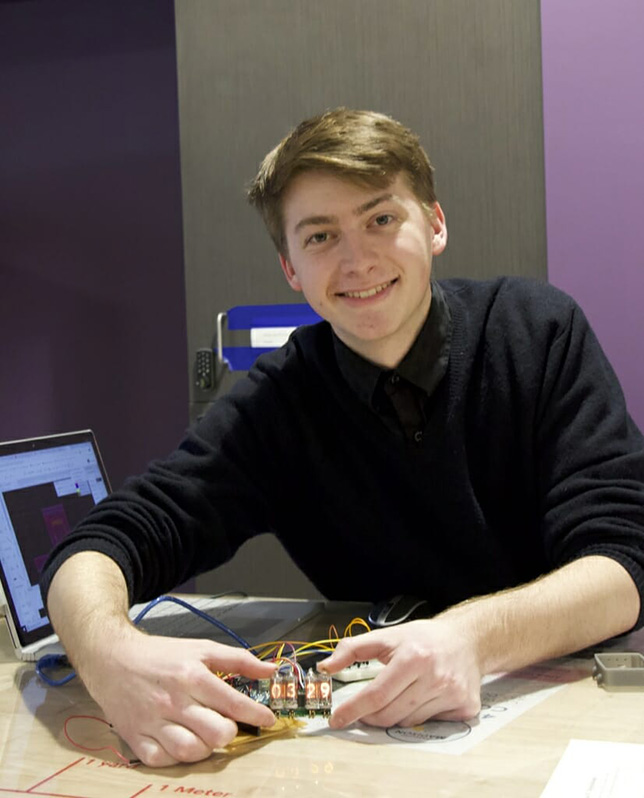

Ian Hogenkamp, a mechanical engineering junior, shows off his "nerdward watch," which displays the time on neon vacuum tubes. Photo by David Tenenbaum.

As one student explained, Makerspace, as it's called, is "the hub for rapid prototyping on campus." According to Taylor Waddell, a third-year mechanical engineering student who coordinated the event, "The central idea of making is, if I have a problem, what is the quickest way to solve it? The solution may not be going to buy a product. Maybe it's better if you make it."

He added that the reverse nature of the career event was a "a great way" for students to show off their projects and prototypes. "Typically, at a career fair you just hand out your resume. If you bring your prototype here, and show it to the company reps, that's a little more personal; it will create a better relationship."

Biomedical engineering students Ben Knudsen (left) and Janmesh Patel demonstrate a pen they're developing to mark tissue during breast surgery performed under infrared light, which helps a surgeon see cancer cells. The pen will also contain conventional ink to mark tissue for evaluation and treatment in daylight. The device combines off-the-shelf parts with 3D-printed parts and is being built under the guidance of plastic surgeons at UW Health. Photo by David Tenenbaum.

Among the employers present was Georgia-Pacific, which sent Arinne Lyman, research and development manager from its Wisconsin R&D facility. "If you have the talent and initiative and more specifically an interest in lifelong learning and an entrepreneurial spirt, you will fit well into our company culture, and we want to have a conversation about your goals and interests," said Lyman.

About the Author

Dian Schaffhauser is a former senior contributing editor for 1105 Media's education publications THE Journal, Campus Technology and Spaces4Learning.